LightWorks llc

We are Continuous Improvement Professionals- Your Partners to transform your performance

We combine more than 30 years of experience with LEAN and Six Sigma methodologies to build cultures of excellence, solve critical problems, and enable employees’ capabilities to unlock the potential of corporations.

Our Services

Customized Continuous Improvement Solutions for your needs

BUILD

Define, develop, and implement an organization-wide Continuous Improvement program, specifically tailored to your organization’s context.

SOLVE

Assess, investigate, and solve your critical issues. Work seamlessly with your teams to both resolve current issues or to proactively develop & launch predictable processes.

ENABLE

Teach, coach, and mentor your employees to have Continuous Improvement competencies. Implement the culture, routines, and KPIs to realize & sustain improvements.

How LightWorks Bring Value

Our clients engage LightWorks to collaborate with strategic suppliers to build win-win improvements, to visualize internal processes, and to recover stalled projects.

Contact LightWorks to realize these improvements for YOUR organization.

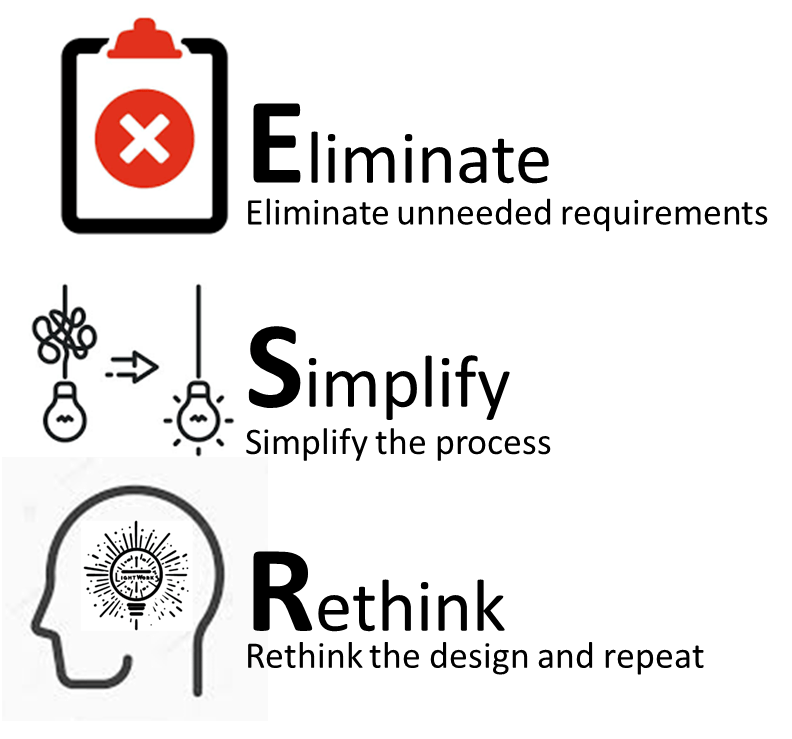

LightWorks has developed a practical and integrated approach to process improvement. Tradition methods are hard to understand and difficult to relate to your work. The EaSieRTM Approach gets results in an easy to understand and easy to apply method.

Contact LightWorks to learn more about the EaSieR Approach

Why Continuous Improvement?

• Manufacturing scrap and rework can cost companies between 5% and 30% of their total manufacturing costs. (Link HERE)

• Nearly 75% of employees are not engaged, costing over $550 billion per year. (Link HERE)

• Employees spend 26% of their day on meaningless activities. (Link HERE)

• Organizations with engaged employees are 23% more profitable. (Link HERE)

• Process inefficiencies costs organizations 30% of annual revenue and 20% of direct cost. (Link HERE)

“A lot of people interpret the Quality role as someone who should bring rigor in following the rules… but that is not enough… you helped bring… the idea that the quality role is not simply that… you correctly highlight that the main part of the role is to help the people and the company understand how to simplify the processes to make them better. Because easy processes mean low probability of errors, more efficiency, and at the end more value for the company.”

– Operations Manager

Contact LightWorks to learn more about Continuous Improvement

“Many thanks for your past (and future) help. You and your (team) are an important part of (our) Team!”

– Senior Vice President, Engineering

Barriers to Getting Started

Continuous improvement is not just a buzz phrase; it’s a fundamental concept that resonates with anyone seeking excellence. The path to delighting customers and maximizing margins lies in identifying and addressing inefficiencies, eliminating defects, and building products or services “right the first time.” But if this approach is so obvious, why do organizations still struggle to implement it effectively?

Business and function leaders are astute individuals who understand what needs to be done. However, they often seek guidance on the “how.” Let’s address some common questions:

- How to Implement a Continuous Improvement Initiative? Defining a practical and organization-specific continuous improvement program is crucial. LightWorks can provide thought leadership to tailor a program that aligns with your unique context.

- How to Sustain the Momentum? Deploying the program across your organization requires more than just enthusiasm. LightWorks offers training and ongoing support to ensure sustained progress.

- How Will People Know What to Do? Clear communication and alignment are essential. We help connect your employees’ daily work to the overarching vision, fostering a culture of improvement.

- Where to Find the Right Expertise and Talent? LightWorks brings expertise to the table. We guide you in assembling the right team and leveraging their skills effectively.

Contact LightWorks to learn more about getting started

LightWorks Approach

LightWorks llc solves problems. We solve problems through a proven process based on LEAN, Six Sigma, and practical experience.

LightWorks llc can:

1. Take on your problems, develop & implement solutions.

2. Teach and mentor your organization to develop & implement solutions.

3. Provide thought leadership to develop your continuous improvement programs.

4. Work directly with your suppliers or customers to address quality issues.

“Impressive… Peter and his team came in on short notice, but met our needs… The details I now have… with meaningful recommendations are highly contributed from Peter…”

– Director of Engineering

Contact LightWorks to learn more about the LightWorks approach

Testimonials

Showcase

Examples of some of our customers’ successes

Medical Equipment OEM

New Product Development

Product & Process Development

Problem: CT Develop cycle ~10 years, with first 3 years addressing process and design issues.

Solution: DFM and 3P. Concurrent engineering of process and product. Resulting in Design to Launch in 3 years and capable processes.

Innovation: Design complexity score, production line mock-ups, supplier process development.

Nuclear Power Operator

New Reactor Cooling

Technical Problem Solving

Problem: Critical cooling system suffered catastrophic vibrations, degrading mission readiness.

Solution: Analysis of failure through fault-tree analysis targeted pump inlet design to cause cavitation. Redesign pond geometry.

Innovation: Implementing a priority & feasibility dimensions to rate possible solutions.

Engineering Services

M&A and Integration

Assessment & Value Roadmap

Problem: Acquisition target operating processes unknown to interested buyer, who operates in strict regulatory environment.

Solution: On-site Gemba walk to assess processes. Risk defined and mitigated in integration plan.

Innovation: Risk informed decision enabled M&A. Value creation roadmap & plan built into integration strategy.

Contact LightWorks to learn more about these and other examples

Where we have worked

LightWorks llc Privacy Policy

LightWorks values the privacy of our clients and have implemented this privacy policy to protect their confidential or proprietary information (“sensitive information”).

LightWorks will not share, distribute, sell, or otherwise provide our clients’ sensitive information to third parties. In the course of business, it may be necessary to contract third parties to support execution of contract elements; however, no sensitive information will be shared without the documented approval of the client’s representative.

If there are concerns or suggestions regarding this policy, please contact our chief executive directly at peterchan07@outlook.com.