Why I Love Buying a Car: A Guide to Prioritizing Decisions, last article in 4 article series.

February 7, 2025

I love buying a car. Many of my friends and family think I might have a few screws loose when I tell them this. To them, buying a car is a headache-filled, nightmare scenario where they feel both manipulated and cheated. On the contrary, I really enjoy the sport and spectacle of the entire process. The process seems straightforward, right? Pick a car you like, find out who has one, identify price, pay for it, and enjoy your car. Unfortunately, I just described buying a pair of jeans. The car buying process is fraught with choices, options, profit margins, and some seemingly black magic considerations like incentives, inventory levels, competition, and substitution. Along with all of these considerations are your emotions, desires, and needs. When there is so much going into a single decision, making a sound decision is no easy feat.

Welcome to the fourth article, the last in the series, of the LightWorks Tools series, where we will address Prioritizing. In previous articles, we covered visualization, analysis, and solutioning. Just like buying a car, when you are solving a problem, you are inundated with ideas and possible solutions. Each one requires different resources, has unique advantages and disadvantages, and can cost differently. Prioritizing the list of solutions is critical to picking the best one to implement, and this can be done with a Pugh matrix.

Pugh Matrix

Application

A Pugh matrix is a tool that lists all the considerations important for a solution. Each consideration is assigned a level of importance. If a consideration is very important, it will have a higher number. Once the characteristics of the desired solution are determined, you grade the possible solutions based on how well they meet these characteristics. The solution with the highest score is the clear winner.

Operation

The Pugh matrix is the reason why I love buying a car. It takes all the subjectivity away and gives me a clear winner. Where there are deficiencies, I can inform the car dealer and see if they are willing to address them. Using the car buying experience as an example, some key considerations from my last car purchase were:

• Price: I wanted to hit the used car price point. For the 3-year-old car I was buying, I required it to be less than $30,000. This was a very important consideration, so I gave it a relative value of 9.

• Equipment: I wanted leather seats and a full infotainment system. It was important, but not as much as price, so I gave it a value of 5.

• Color: I am a fan of monochromatic styling. Combinations of black on black, or black on white, were high on my list and of medium importance, so I gave it a value of 5.

My actual list had 27 considerations, but I’ll suffice this discussion to these three for illustration.

Equipped with my list of what I wanted, I looked for available cars and called on the salespersons. I made visits to the finalists, dealers with the highest scores. Once the solutions are identified, they must be evaluated to determine to what extent they meet the considerations. For this illustration, if the solution provided the consideration to a high extent, it scored 9; if to a medium extent, then 5. In the next section, we can see how the scores are multiplied and added to compile the Pugh matrix.

Action

Once I had all the offers from the dealers, I could score the proposals against my requirements. Let’s complete the Pugh matrix with some dealer proposals:

• Proposal 1: $29k, Black on black, full infotainment

• Proposal 2: $32k, White on beige, full infotainment plus hotspot, satellite radio, OnStar

• Proposal 3: $26k, Yellow on beige, basic radio

Scoring

• Proposal 1: Price met my needs to a high extent (9×9=81), Color to a high extent (5×9=45), Equipment to a high extent (5×9=45). Total score 171.

• Proposal 2: Price, medium extent (9×5=45), Color medium extent (5×5=25), Equipment medium extent (5×5=25). Total score 95.

• Proposal 3: Price, high extent (9×9=81), Color low extent (5×0=0), Equipment low extent (5×0=0). Total score 81.

The clear winner is Proposal 1, with unemotional feedback to Proposals 2 and 3 on what their shortfalls were. Is car buying now fun?

Pro Tips

• My example is simplistic; actual decisions will have many considerations. Use a spreadsheet to keep track and automate the calculations.

• Set up the scoring in one direction only to avoid contradictions. For example, set up favorability to be the high score. This will avoid errors of one consideration negating another.

• A Pugh matrix is intended to score the most important considerations, while assuming lower-level considerations will cancel out. Do not overly complicate the Pugh matrix.

The next time you need to make a complex decision, like buying a car, try using the Pugh matrix. You will go into the process clear and have a stress-free experience.

We hope you enjoyed our tools series and found it useful. Please leave us your comments!

Contact LightWorks LLC for more information or visit our website

Contact: https://makeworklight.com/contact/

Website: https://makeworklight.com/

The Stuck Truck: A Lesson in Lateral Thinking, third article in 4 article series.

January 31, 2025

The story of the stuck truck is my favorite example of lateral thinking. Though it may be more urban legend than fact, it serves as a great way to approach problem-solving. As a Chicago native, I know firsthand the many bridges and underpasses that crisscross the city. For high-profile vehicles, it must be a constant worry that your truck will get stuck and damaged if you inadvertently drive into an underpass that is shorter than your truck. I’ve seen many times a poor driver standing by the side of his miserably stuck truck with the top of it peeled off like a SPAM can.

As the story goes, a truck has gotten stuck under a bridge, and no amount of backing up or moving forward is possible. The driver is now out of the truck, and mechanics and engineers are on the scene. The mechanics are determining how best to deconstruct the truck to shorten it, while the engineers are assessing how to remove sections of the bridge. This situation seems difficult to resolve.

Then, a child riding along the sidewalk on his bike simply makes an observation to the driver: “Hey, mister, why don’t you let the air out of the tires if your truck is stuck?” This elegant but simple solution took minutes to implement at no cost. The truck was backed out of the underpass, and the problem was solved. The mechanics were called in for their expertise on how to fix the truck, while the engineers were called in for theirs on how to address the bridge. These were two independent linear thinking paths. The solution required a different, lateral thinking path.

Welcome to the third article of the LightWorks Tools series, where we will address Solutioning. In previous articles, we covered visualization and analysis, and in the next, and last in the series, we’ll dive into prioritizing. Finding the best solution for the circumstances is a fine blend of innovation, resourcefulness, practicality, and urgency. A solutioning tool that promotes this type of collaboration across these laterals is “brainstorming.”

Brainstorming

Application

The premise of this tool is very straightforward: simply write down the ideas that come to mind without overthinking the details or criticism from others. In other words, just “spit” it out. What is happening is actually complex and fascinating, and is guided to make sure the brainstorming is effective. When done effectively, brainstorming will yield a broad array of potential solutions that can be blended or combined to form more comprehensive ideas.

Operation

Assemble the proper team for the session. Using the “stuck truck” story as guidance, ensure you have a few experts who can represent the appropriate disciplines, but also include those who can provide perspective and lateral thinking. If solving a technical problem, certainly have the engineers and technicians, but also consider the salesperson. When solving a customer issue, include the sales and services folks, but also consider the supplier. Once the team is assembled and everyone is briefed on the situation, follow the 7 formal rules of brainstorming, plus 1 more from my experience:

- Don’t judge. When ideas are presented, take them at face value. Judging ideas shuts them down or channels the thinking into unhealthy directions.

- Encourage “wild” ideas. Try to break away from the normal thinking track.

- Make it visual. Write ideas on sticky notes and post them up for everyone to see. This will spark ideas in others.

- Encourage “stealing.” Take an idea that was raised and make it yours; put your twist on it.

- Quantity over quality. Don’t overthink the idea; try to get as many out as possible.

- Avoid bunny holes. Avoid groupthink.

- Have fun. The intent is to be creative, and often it’s funny.

- The plus 1 is 7. Try to come up with 7 ideas per person. The science is that we can quickly generate 2-3 ideas, but they often fall into the “old and boring” category. The next few ideas may be a little lateral but still somewhat linear. When you get to 6-7 ideas, you’re uncomfortably lateral in your thinking.

Action

Once the brainstorming session concludes, you will have a good number of ideas. Systematically evaluate the ideas and identify ones for implementation. In complex issues with no clear solutions, selecting the idea to implement may be difficult. We will address that in the next article, but suffice it to say that there was a clear solution. As part of the detailed planning to implement the idea, consider carefully the question:

“How will we know if the solution was successful?”

Do not simply implement a solution and walk away assuming the solution addressed the defect. Pick the relevant measure and verify the defect is addressed. In the stuck truck story, the measure for success may be the space between the truck and bridge needs to be greater than zero, or the weight of the truck must not be heavier than the actual weight, etc.

Pro Tips

• Avoid having dominating personalities in the solutioning process; they will always derail the discussion.

• When ideas slow to a trickle, call on people for their ideas in turn, but allow them to pass their turn if they do not have a new idea. This positive pressure heightens thinking.

• Break the train of thought of the group if they are group-thinking by injecting a new line of thinking, such as “What kinds of ideas would you have if cost was no object?”

The next time you need a solution, give brainstorming a try. You will be amazed by the creativity and variety of ideas that result.

Contact LightWorks LLC for more information or visit our website

Contact: https://makeworklight.com/contact/

Website: https://makeworklight.com/

The Art of Analysis: From Windshield Wipers to Root Cause, second article in 4 article series.

January 23, 2025

I like to believe that I am a competent handy-person. I take pleasure and pride in completing repairs through my own skills and efforts. One of my proudest moments was troubleshooting and repairing the windshield wiper motor failure of a 1978 Mercedes Benz 300CD. This car, with its 1970s classic chic, was a gorgeous diesel Mercedes coupe. Despite the odometer approaching 300,000 miles, it continued to purr like a kitten. When the wipers stopped working, I pulled out all the electrical diagrams and isolated a relay that controlled the failed functions. After repeated rejections at Mercedes sources for this relay, I cross-referenced it to a standard Bosch automotive relay. Voila! I found the part for $5 at my local electronics parts store, installed it, and presto—working wipers. I take great joy in telling this story because, often, my repair projects are typically full of frustration and wasted effort. What seems like a 30-minute repair can take many hours and multiple trips to the parts store, with spare parts piling up and no effective repair in sight.

What makes the difference between an effective repair and one that is not? Analysis. A proper analysis will identify the true cause, whereas a hasty or ineffective analysis will send you down the wrong paths. Welcome to the second article of the LightWorks Tools series, where we will address Analysis. In the previous article, we covered visualization, and in the next two articles, we’ll dive into solutioning and prioritizing.

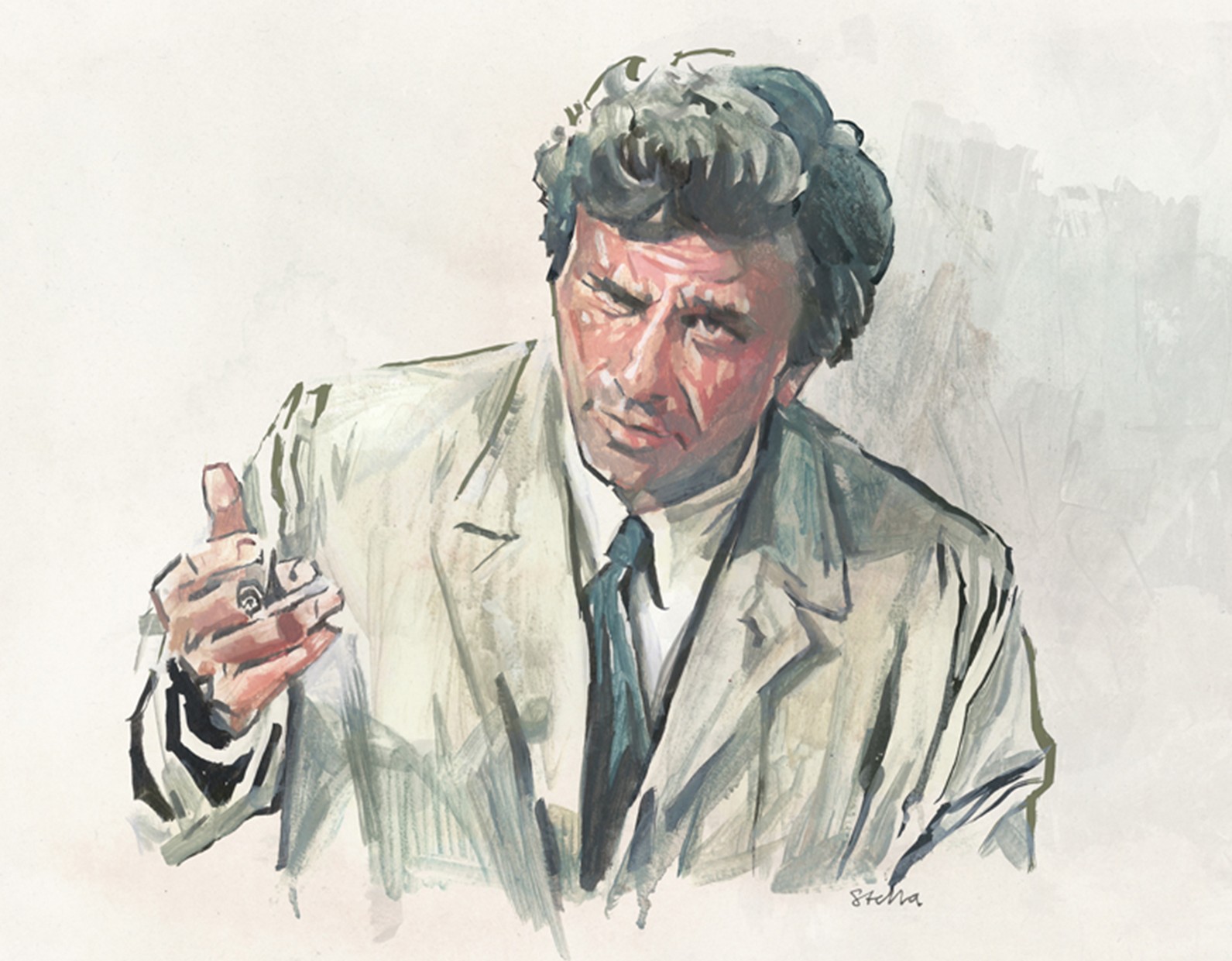

Analysis is akin to being a detective. You have the corpus delicti (the defects), the crime scene (the process), and now you have to find “whodunit” (who did it, or who committed the crime). There are many effective tools to choose from, each with its own strengths and can be more appropriate for specific situations. One tool I often find investigators start with is the “Five Whys.” It is a great tool because of its simplicity and provides a good initial analysis before more sophisticated techniques are needed.

Five Whys

Application

The premise of this tool is to systematically, in a Socratic fashion, ask the question “why” until you get to the origin of the problem. In problem-solving terms, you want to get to the “root” cause. In deference to my friends in the nuclear industry, the root cause means a very deeply researched cause that can be unequivocal. For this discussion, I will use the term “the most practical and probable cause” (PPC) instead of root cause.

Operation

While focusing on the defect, simply ask the question “why did the defect occur?” Once you have an answer, then ask the next “why”: why did this occur? Continue this line of questioning until you reach the PPC. The rule of thumb is to try to get to five layers of why; however, in my experience, PPC can be found in as few as three layers of why. Let’s demonstrate this with an example:

Defect: My tire is flat

- Why is the tire flat? There is no air in it.

- Why is the air out? There is a hole in the sidewall.

- Why is there a hole? I drove on a nail.

- Why did I drive on a nail? The nail was on my driveway.

- Why was there a nail on the driveway? I had roofing repairs yesterday.

Thus, Socratically, the flat tire was caused by roofing repairs.

Action

Once the PPC is determined, take actions to correct the situation so you will not get a flat tire the next time you drive on the driveway. You can sweep the driveway with a magnetic broom. Even better, prevent getting a flat tire altogether the next time roofing repairs are needed by including sweeping as part of the repair process to prevent future defects.

Pro Tips

• Asking the five whys about the defect can certainly get you to the PPC, but it is still one-dimensional.

• To add another dimension, ask five whys about detection: “Why was the defect (or conditions for defects) not detected?”

• Add a third dimension and ask about the environment, such as people’s attitudes about the defect, by asking: “Why was the defect allowed to occur?”

• Together, asking about these three dimensions, the tool now becomes a “three-legged, five why.”

Go ahead and practice either the Five Whys or the Three-legged, Five Whys the next time you have a defect to investigate by channeling your best internal detective.

Contact LightWorks LLC for more information or visit our website

Contact: https://makeworklight.com/contact/

Website: https://makeworklight.com/

Mastering Continuous Process Improvement: Tools and Techniques for Success, first article in 4 article series.

January 17, 2025

For as long as I can remember, mechanical tools and the mechanisms they fix have fascinated me deeply. From the micro-screwdrivers used by horologists to adjust the motion of a watch movement, to the underwater welding torches used by construction divers to build bridges, each tool serves a specific purpose and requires a skilled user. The concepts behind these tools are simple, but their application and the expertise needed to use them effectively are what make them invaluable. A horologist can make precise adjustments to a Patek Philippe watch movement with a micro-screwdriver, but in my hands, the same tool might turn a delicate timepiece into rubbish!

I use this tool metaphor to illustrate the tools used in continuous process improvement. At first glance, these tools may seem simplistic, especially to highly skilled users such as engineers, managers, and designers. However, from my experience, the true value lies not in the physical use of the tools, but in how they are used and the insights they provide.

In a series of four articles, I aim to provide you with three reference points for continuous process improvement tools:

• Application: When to use the tool.

• Operation: How to “run” the tool and obtain relevant results.

• Action: What to do with the outcomes.

I will categorize the tools into four sections, and the subject of each article, that I hope you will find useful:

- Visualizing

- Analyzing

- Solutioning

- Prioritizing

In this first article, let’s start with Visualizing. To fix something, you must be able to see, perceive, and understand it. In physical processes, like a manufacturing line, this is straightforward. For example, in a steel mill with electric arc furnaces, the heat of molten metal cauldrons and the loud hammering of forges viscerally engage you. On the other hand, transactional processes, like purchasing, exist on paper and are not as visually apparent. Regardless of the process, we need tools to fully visualize it to follow it properly. More importantly, proper visualization of a process quickly reveals deviations. The Process Flow Diagram is a very important visualization tool.

Process Flow Diagram

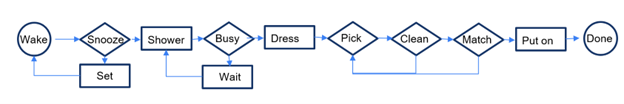

A Process Flow Diagram provides a step-by-step characterization of a process, making it easy to understand what is being done. These diagrams can range from simple, high-level depictions to very detailed and granular definitions. The depth of the process map depends on its intended purpose. A high-level map may be appropriate for training purposes, while a detailed diagram may be needed to troubleshoot defects. For this article, we will focus on a high-level diagram as a starting point, adding more details as needed.

Application

As with learning any language, you must be familiar with its building blocks, much like letters of the alphabet for English. You can read this sentence because you understand the letters. Process Flow Diagrams also have a language. Here are the basic building blocks:

• Ovals and Circles: Starting and ending points.

• Rectangles: Process steps.

• Parallelograms: Process inputs and outputs.

• Diamonds: Decision points.

• Arrows: Connecting shapes, indicating the flow from one operation to the next.

As you become more advanced, you will need more shapes to depict your process, but these five basic shapes are a good start. For a larger library of shapes, visit the ASQ website.

Operation

A Process Flow Diagram visually connects a starting circle to an ending circle with arrows linking shapes in between. The words written in the shapes describe each step in the process. Here is a simple process flow for waking up in the morning:

1. Start (The moment before the alarm rings, but still asleep)

2. Alarm rings (Decision: Snooze or Wake up)

3. Get out of bed

4. Brush teeth

5. Get dressed (Decisions to ensure clean and matching clothes)

6. End (Ready for the day)

Action

With this visualization of the process, the next step is to analyze it to find where you have the most defects, where you spend the most time, or identify steps that do not make sense. The Process Flow Diagram makes these issues obvious.

Pro-Tips

• Start at the beginning: Pick the perspective of the object you are building. In the above flow, the object is me, in a sleeping state, in bed. Then, step by step, determine the process with the simple question: “And then what?”

• Start at the end: Some processes can get messy in the middle, especially if they are not well understood. Start with the finished product your customer expects. In this case, it is me, awake and dressed. Once you determine the process end, ask the simple question: “What happened to cause this?”

• Don’t go too deep at the beginning: Many teams get bogged down in the molecular details of a process and lose sight of the overall picture. Start with high-level steps to connect the endpoint, then go back to ask deeper questions.

• Go to the Gemba: Create the diagram where the process actually happens. Write down what actually occurs, even if it differs from the procedure. Ask experts and operators for their input.

Practice building a Process Flow Diagram of something fun, like brushing your teeth. Actually, brush your teeth, then compare what you did to what you thought you did. You will find gaps in your perception versus the actual process. You’ll be a local expert in no time.

Contact LightWorks LLC for more information or visit our website

Contact: https://makeworklight.com/contact/

Website: https://makeworklight.com/

Applying Detective Skills to Continuous Improvement: InnoTech Case Study, last article in series of 3

January 3, 2025

I am a tremendous fan of detective television series and cling to reruns of popular 1970s detective shows. There were many: Columbo, Kojak, McCloud, Barnaby Jones, Cannon, Baretta, Quincy, and then the ones with partners, such as Starsky & Hutch, CHiPs, Charlie’s Angels, and many more. The central theme is usually finding the right evidence to apprehend the law-breaker, usually a murderer, through careful analysis of the crime and crime scene. This is exactly the same premise as Continuous Improvement. Go back to the scene to make systematic observations and catch the defect-generating or time-wasting perpetrator. In LEAN, the Japanese term often used is “gemba,” which is literally translated as the “actual place.” Japanese news reporters will refer to a crime scene as the gemba, thus bringing the reference full circle to apply investigative techniques at the gemba to solve the crime.

In the last article in the series of three, let’s revisit InnoTech. Executive leadership at the company has realized the need to protect, defend, and grow the company’s margin. The most effective way is to improve the “quality” of the processes, which leads to reduced requirements, reduced defects, reduced effort, and ultimately reduced cost. A word of caution here: the reverse is catastrophically untrue. Simply removing cost does not improve quality or reduce effort; it is wishful thinking at best and destructive at worst. LightWorks helped InnoTech focus on the operation’s largest costs: purchased materials from suppliers. A strategy was developed and an effort launched with key suppliers to identify quality and effort-saving ideas. In return, the supplier would share the resultant cost savings as a price reduction. This would be a win-win situation for both InnoTech and their key suppliers.

LightWorks planned and facilitated workshops between individual InnoTech suppliers and the corresponding InnoTech functional owners, such as engineering, purchasing, quality, manufacturing, etc. Within the workshops, LightWorks applied applicable analysis, idea generation, and prioritization tools to develop and assess ideas to improve quality and reduce effort. Ideas fall into four general categories:

- Elimination of requirements: Requirements are expensive, especially if they stray from the norm. Henry Ford’s famous quote about the Model T, “You can have any color you like, as long as it is black,” teaches us that standard products optimize cost and, just as importantly, reserve costs for where they are needed. The gemba for requirements should be the end customer; you should be able to trace product requirements directly to customer needs.

- Simplification of process: Once requirements are fully vetted, the next focus is the process and specifications. In the famous words of W. Edwards Deming, “It is not necessary to change. Survival is not mandatory.” In Dr. Deming’s cunning, his quote tells us that if we want to survive, we need to change. Identify areas where there are defects, rework, or excessive time spent. The gemba is on the supplier’s manufacturing floor, where the part is literally produced.

- Redesign the part: Once all requirements are vetted and all processes scrubbed, the final countermeasure is redesign. Design out the complexity or design in the requirement.

Although the overall effort can be distilled into these three courses of action, the work is complex and, in a regulated industry, can require design validation, process validation, and sometimes regulatory approval. This effort at InnoTech is a multi-year journey with this as the first step.

To date, we have completed ideation sessions with tens of strategic suppliers and identified over 150 improvements, some of these are no-brainers to implement, whereas others will take major redesigns to realize. In total, the current funnel of ideas is worth over $3 million in COGS savings.

Does the InnoTech story resonate with you? Are there any similarities between this story and the problems you deal with today? Contact LightWorks to begin your journey.

Contact LightWorks LLC for more information or visit our website

Contact: https://makeworklight.com/contact/

Website: https://makeworklight.com/

Challenging the Status Quo: A Lesson from InnoTech, 2nd article in a series of 3

December 26, 2024

Do you ever wonder why things are the way they are? I was a very curious child, always needing to understand how things worked and why. I took apart countless toys and gadgets, much to the chagrin of my family. I am dating myself here, but on my first airplane trip, I took apart the armrest to understand how sound was coming through a tube and into my ears. For those who need an explanation, the technology was called “pneumatic audio.” Your “headphones” were basically plastic tubes going into your ears and plugged into the armrest. Depending on the system, the actual sound could have come from small speakers in the armrest or perhaps from a more central location. I found the speakers, and the flight attendant was not happy with my project.

Today’s article, the second of three, explores our human tendency to accept what already exists. This bias is so strong that it causes us to reject any type of change from the norm, even when the norm makes no sense.

Let’s revisit InnoTech. The company has developed technology to precisely deliver treatment for a disease that is 90% more efficient than the standard of care. Once the business became viable and factories were built, the original process to build these machines was scaled up from the first units. Growth involved building factories, buying tools, and hiring personnel. As demand for this amazing technology skyrocketed, the factories were stretched, supply chains thinned, and more growth was needed. More sources were sought, and supply lines became deeper, broader, and more complex. With so much going on, between developing next-generation innovations to stay ahead of the competition and managing explosive growth, there was no appetite to go back and change anything. Issues would arise from suppliers and manufacturing, with suggestions for improvement; however, with so much going on, Engineering did not have the bandwidth to make any changes. This led to the rejection of improvement ideas and later fostered a culture of acceptance of the norm and an unquestioning attitude toward issues.

This situation is what I call the “Ham Doctrine.” I give a full description of this doctrine in an earlier article, so please refer to that article for details. The gist of the doctrine is simply unquestioned compliance, even if it does not make sense. To the defense of InnoTech and every leader out there, balancing priorities is no easy task. Focusing on one thing can cause issues elsewhere. When the focus is on speed to market and innovation, process development and optimizations fall to the wayside, and vice versa.

The situation for InnoTech is the result of their own success. After years of delivering innovative products and developing the precision therapy delivery market, competitors were attracted to the market. With competitors driving to take market share, economic pressures driving prices down, and rising costs, profit margins hit an all-time low. The focus now needs to be on driving costs out of the product. Like many producers of large capital equipment, the lion’s share of product cost is in supplied goods. The reality today is that products are largely sourced from suppliers, with only final assembly and testing happening at the manufacturer. LightWorks was engaged to help.

Are there any similarities between this story and the problems you deal with today? Stay tuned for how InnoTech addressed the situation together with LightWorks.

Contact LightWorks LLC for more information or visit our website

Contact: https://makeworklight.com/contact/

Website: https://makeworklight.com/

Applied Continuous Process Improvement: A Case Study, 1st article in a series of 3

December 19, 2024

Continuous process improvement concepts are straightforward and make a lot of sense when read about or seen presented. If this is the case, then why do US productivity numbers continue to decline? In the measure of Gross Domestic Product (GDP) versus hours worked, productivity grew 4% in 2020, only 1.4% in 2021, decreased to 1.1% in 2022, and saw another reduction to 0.7% in 2023. From a national perspective, we are spending more time creating less value! This is certainly a complex problem with many contributing factors, such as the COVID-19 pandemic, which caused major disruptions in labor and supply chains. In the post-pandemic economy, we have new levels of normal that we must adjust to. We have the proven tools, but we need to awaken from the fog of the pandemic, get back to basics, and rebuild the productivity we lost.

Often, the “what” needs to be done is easy to define, but the decision and alignment for “how” it should be done usually derail any meaningful actions. In a series of three brief articles, I will provide examples of how one of my clients took action. I will use a fictitious name and obfuscate identifying details, but the actions, decisions, and results are real. In this first article, I will lay out the scenario my client company faced.

Case Study: InnoTech – Providing innovative treatment technologies.

“InnoTech” (a fictitious company name) was founded over 30 years ago by several brilliant researchers at a major State University. The technology they developed enabled therapy that was so precise that treatment times and sessions could be reduced by nearly 90%! A patient can be treated in 5 sessions with InnoTech technology, versus more than 50 for traditional therapies. Can you imagine going to the treatment center 90% fewer times? This is a significant savings in both the patient’s and the treatment center’s time and resources, not to mention the mental well-being of the patient with 90% fewer sessions to endure.

As with many start-ups on the cutting edge of technology, all focus was placed on making sure the technology worked, was safe, and was effective. Nothing else mattered. Once the technology was demonstrated, the processes and designs were locked in over 30 years ago. Initially, many of the original researchers and engineers were working hand-in-hand with manufacturing and their suppliers to make the first few units. This type of close support became less feasible with more units being ordered, factories getting busier, and the supply chain getting more dispersed. We’ll explore the types of issues these conditions set up in the next article, but for now, I will leave you with a personal example.

A Personal Example

My middle son is incredibly ambitious and has the confidence of a Spartan. One evening, he was determined to make the family his favorite dinner: spaghetti with Italian sausage sauce. He absolutely knew the requirements because he wanted to produce the meal he designed, without customer input. He did not want mom’s help and wanted it to be his own creation. After a few hours, with a lot of disturbing noises coming from the kitchen, dinner was served. To his credit, he plated and served the meal; it was “safe” to eat from a food safety perspective, but we all had to put on brave faces to finish the meal. The surprise was a tour of the kitchen after dinner. Dirty dishes and tomato sauce were everywhere. There was spaghetti on the ceiling and sauce on the curtains! The product was made and delivered, but the customers were not enthused, and operations were a mess, literally!

Are there any similarities between this story and the problems you deal with today? Stay tuned for how InnoTech addressed the situation.

Contact LightWorks LLC for more information or visit our website

Contact: https://makeworklight.com/contact/

Website: https://makeworklight.com/

The Efficiency Fallacy: Why More Isn’t Always Better

In my morning news feed today, there was an article published by a prominent business school review that argued that governments should be effective, but not efficient. As a continuous improvement aficionado, this certainly piqued my interest. The article’s general point was that governments don’t work as cheaply and quickly as they could, and that can be good. Some examples include:

• We don’t want law enforcement to be fuel efficient when in pursuit of an offender.

• We don’t want the courts to be efficient in the administration of justice.

I can understand the author’s intent for the premise and the examples. We certainly do not want our law enforcement to potentially prioritize fuel consumption over criminal apprehension. Similarly, we do not want our judiciary system to prioritize speed to case closure over justice. However, the author is perpetuating the false “fallacy of efficiency.” The fallacy of efficiency is simply the unfounded belief that more is better, while less is worse. If a process takes an average of 3 hours to complete, then taking 4 hours would be better. On the other hand, if it took 2 hours, the fallacy would be an expectation of less quality. Indeed, if you simply eliminated a resource required for a process, time in this case, then certainly, the process cannot be properly completed. Removing resources is not improving efficiency; rather, it is irresponsible tampering with the process. In order to drive efficiency and realize actual benefits, the underlying process must be investigated and the source of the inefficiencies either eliminated, simplified, or redesigned. This is indeed improving efficiency, to get higher quality results while consuming fewer resources. Let’s not embrace process tampering, but rather process improvement, to drive efficiency.

I cannot fault the author for falling into the false fallacy of efficiency misconception because in my more than 30 years of working with processes and leaders from many industries, the misconception is pervasive. I have seen very seasoned operational leaders simply remove 20% of the next year’s operating budget to show achievement of the 20% efficiency without addressing the underlying processes or cost structure. Operations are set up to fail. We can work to break this false fallacy with a few simple steps to drive efficiency:

1. Visualize: Get a clear view of the overall process, step-by-step. This includes understanding how long each step takes and the defects that can occur.

2. Eliminate: Where there is a lot of time or defects, focus on that area to identify steps in the process to eliminate. Using an industrial example, welding is a complex process, but it can be eliminated if it were replaced with a bolted connection.

3. Simplify: In areas that cannot be eliminated, work to simplify them. Using the ordering process as an example, the need to gather the customer’s order cannot be eliminated, but when it is simplified, the customers have a better experience with fewer mistakes on the order.

4. Redesign: Where elimination or simplification is not possible, redesign it.

To bring this back to governmental effectiveness and efficiency, we do want law enforcement and the judicial system to be more effective when process inefficiencies are addressed to free up more resources to be even more effective.

#Efficiency #ProcessImprovement #ContinuousImprovement #OperationalExcellence #LeanManagement #BusinessStrategy #GovernmentEfficiency #EffectiveLeadership #Productivity #QualityManagement

Building a House in less than 3.5 hours: Lessons in Process Improvement

In 2002, in Shelby County, Alabama, USA, a 1,200 square foot house with 3 bedrooms and 2 bathrooms was built in an astonishing 3 hours, 26 minutes, and 34 seconds.

You can observe in the house video:

Production Preparation Process (3P): Everything from material staging, positions of equipment (like the crane to lift the roof on the frame that is still being built!), and timing of the processes (TAKT) needed to be meticulously choreographed.

Standard Work and Skilled Craftsmanship: There was no guessing about job expectations, procedures, or quality checks before the next operation. Everything was clear, and the work was completed by highly skilled individuals.

Manual Work vs. Automation (Autonomation): There was a balanced mix of equipment (cranes) and tools (lifting straps, ladders, etc.) to support the manual work effectively, safely, and quickly.

Parallel Processing: Processes that could occur independently were decoupled and completed in parallel, rather than in sequence. For example, the roof was built in parallel to the framing, minimizing the overall duration. There is a common misconception that parallel processing costs more due to increased personnel involvement; however, it is the same cost if you pay 10 people for 10 hours as it is paying 20 people for 5 hours.

I would love to know what your observations are from the house video. Please comment!

Unlocking Continuous Improvement: Practical Strategies for 2025 Success.

I recently came across this excellent LinkedIn article that effectively outlines the challenges of fostering a successful improvement culture. The long-term goal of Continuous Improvement is to cultivate a company-wide passion and automatic response for making improvements at every opportunity.

From my experience, both personally and with my clients, the real friction point isn’t about “what” to do, but rather “how” to do it. This “how” can be broken down into a few key considerations:

1. Practical Application: While LEAN and Six Sigma concepts are straightforward and many intelligent individuals have been trained in them, the challenge lies in their practical application. Questions like which tool to use, how to apply calculations to specific processes, and what the data truly means often create confusion and frustration.

2. Prioritization: Teams entrenched in daily operations often struggle to find time to focus on strategic improvements. A call to action for driving improvements can be ineffective without meaningful discussions about priorities and expectations. This places middle management in a difficult position: they recognize issues that consume time, yet feel they lack the time to address those very issues.

3. Resource Allocation: For an improvement culture to thrive, several truths must be acknowledged:

– It’s Not Free: Implementing improvements requires an upfront investment of time and resources. While it can become self-funding in the long run, initial support is essential.

– Job Changes: As processes improve, the need for certain roles may diminish, which is often a core intent. However, it’s crucial to communicate that any freed-up resources will be redirected toward growth initiatives.

– Availability for Improvement: When inefficiencies stretch team capacities, no one is left to focus on enhancements. Identifying dedicated resources to either assist in daily operations or facilitate process improvements is vital.

As we approach the year-end push, I’d love to hear about your improvement plans for 2025. LightWorks is here to support you with the “how’s” of Continuous Improvement!

From Knowledge to Action: Empowering Organizations with Practical Expertise for Lasting Success

Insightful Reflections on Consulting

I wholeheartedly agree that advancements in technology and the accessibility of information have democratized knowledge, making topics once reserved for experts available to many. As a result, organizations need not turn to consultants for specialized expertise, like LEAN or Six Sigma. However, truly successful organizations recognize that knowledge alone is not enough. While it serves as a foundation, the real differentiator lies in applied experience. Effective consultants, with “battle hardened” practical experience, understand that guiding the execution of an action plan, in alignment with an organization’s core values is essential for achieving meaningful results.

Consultants miss the mark if their primary role is merely to broker information. They create real value by helping organizations translate principles into practical action, fostering a culture of continuous improvement that endures long after their engagement has ended.

As Lao Tzu wisely said, “Give a man a fish and you feed him for a day. Teach him how to fish and you feed him for a lifetime.” This underscores the importance of empowering organizations to sustain their own growth and innovation. This is the value consultants should deliver.

What are your thoughts?

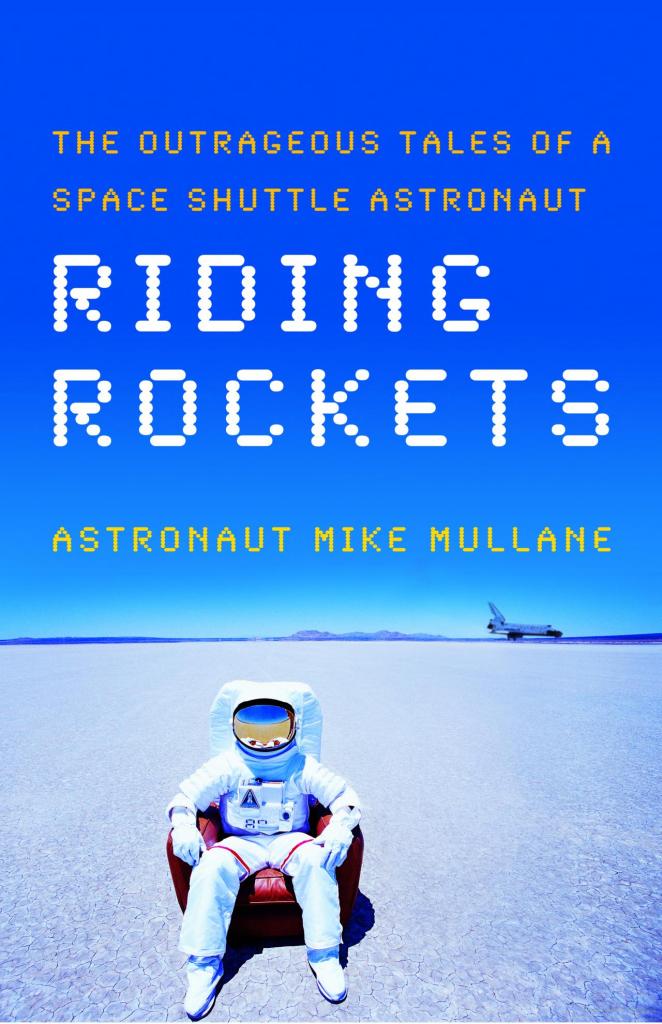

Success: A Double-Edged Sword

One of my all-time favorite autobiographies is Astronaut Mike Mullane’s “Riding Rockets” and it is more than an autobiography; it’s a profound journey from a childhood dream to the stark realities of space exploration. Mullane’s experiences culminate in a powerful teaching moment: success can pave the way to failure if we grow complacent.

In his book and public talks, Mullane introduces the concept of the “normalization of deviance,” using the Space Shuttle Challenger disaster as a cautionary tale. The term refers to the gradual acceptance of lower standards, which, while seemingly harmless at first, can lead to catastrophic outcomes. The Challenger tragedy was precipitated by a series of overlooked deviations from safety protocols, specifically regarding the booster rocket’s O-ring seal. Despite strict specifications, launches proceeded with known defects, leading to a tragic normalization of what was once considered unacceptable.

Continuous Vigilance in Pursuit of Excellence

This narrative serves as a critical reminder for those of us dedicated to LEAN principles and continuous improvement. It prompts us to reflect:

- Where might our successes be obscuring potential failures?

- Are operational cost increases being justified by strong revenue growth?

- Is the allure of lower costs from suppliers causing us to compromise on quality?

As champions of LEAN, we must remain vigilant, ensuring that our efforts to eliminate waste do not inadvertently introduce a tolerance for deviation. It’s essential to maintain a culture of continuous vigilance and unwavering standards, especially when success tempts us to overlook the small details that can lead to significant consequences.

What are your thoughts? I would welcome your private messages to further the conversation.

Shout out to @Mike Mullane

#ContinuousImprovement #LEANLeadership #OperationalExcellence #QualityMatters #SuccessMindset #VigilanceInVictory #ChallengerLegacy #NoRoomForComplacency #ExcellenceInExecution #StandardsMatter

LightWorks LLC Achieves NC HUB and NCSBE Certification

For immediate release

Raleigh, NC – April 22, 2024: LightWorks LLC, a leading provider of innovative solutions, is proud to announce that it has successfully obtained the Historically Underutilized Business (HUB) and North Carolina Small Business Enterprise (NCSBE) certifications. This significant milestone underscores LightWorks LLC’s commitment to excellence and its dedication to fostering diversity and equality in the business community.

The HUB certification is a testament to LightWorks LLC’s efforts to contribute to a more inclusive economy. It recognizes the company’s status as a competitive player in the market, poised to engage in state and local government contracts. Similarly, the NCSBE certification affirms LightWorks LLC’s position as a small business with the capability to compete effectively in industry and market-specific opportunities.

“Receiving the NC HUB and NCSBE certifications is not just an honor; it’s a reflection of our core values and our resolve to be part of the driving force that supports economic growth and development in North Carolina,” said Pete Chan, Chief Executive and Founder of LightWorks LLC. “We are excited about the new avenues and partnerships these certifications will open up for us.”

LightWorks LLC is headquartered in North Carolina and offers professional, management, and process consultation services. LightWorks LLC specializes in Continuous Improvement to help organizations deliver customer value, while engaging their employees and improving quality, that results in increased margins. Contact LightWorks LLC for more information on how Continuous Improvement can unlock your organization’s potential.

For more information about LightWorks LLC and its services, please visit www.MakeWorkLight.com

LightWorks LLC: Illuminating the Path to Inclusive Excellence and Business Innovation

#NCHUBCertified #NCSBECertified #BusinessExcellence #DiversityInBusiness #InnovationLeaders #QualityLeadership #ContinuousImprovement #OperationalExcellence #SupplyChainExcellence #EngineeringExcellence #CertificationSuccess#SmallBusinessGrowth #EconomicDevelopment #InclusiveEconomy #NCevp #NCSupplyChain #NCprocurement

Strategic Cost Management: What is your strategy to manage rising costs?

The unfolding situation in California is poised to become a staple in business school case studies for years to come. At one end of the spectrum, there’s a rightful demand for fair wages by workers. At the opposite end, we find customer price sensitivity, which is not infinitely flexible. My stance is neutral, focusing solely on the economic and mathematical implications of the scenario.

Caught in the middle are restaurant owners like McDonald’s franchisee, Mr. Scott Roderick. The dilemma he faces is clear: increasing wages without the corresponding ability to adjust pricing directly impacts profit margins. Mr. Roderick is actively seeking cost reduction methods. While deferring certain expenses may offer temporary relief, it’s not a viable long-term strategy. Essential costs, such as HVAC replacement or mandatory remodeling to meet current standards, will eventually need to be addressed.

Mr. Roderick is on the correct trajectory, acknowledging the necessity of a strategic approach to drive incremental improvements that counterbalance rising costs.

Business conditions can be unpredictable, with new legislation potentially increasing operational costs or unforeseen events disrupting critical supply chains, as exemplified by the unfortunate collapse of the Key Bridge. It prompts the question: Do you have a long-term strategy to mitigate rising costs, akin to Mr. Roderick’s approach? Are your short-term cost containment strategies designed for sustainability?

We welcome your insights on navigating these complex challenges. For further discussion, please reach out to LightWorks!

Contact: https://makeworklight.com/contact/

Business Insider Article: https://www.businessinsider.com/california-mcdonalds-fast-food-20-minimum-wage-franchisee-cutting-costs-2024-4

Why Lean and Continuous Improvement Programs Fall Short: A Quality-Centric Perspective

In the realm of organizational improvement, Lean and Continuous Improvement programs promise enhanced efficiency, streamlined processes, and better outcomes. Yet, despite these lofty goals, they often fail to deliver the expected results. At best, they fall short; at worst, they inadvertently hinder an organization’s ability to meet customer demands.

The Artillery Shell Supply Dilemma

Consider the recent case discussed in the February 21st edition of Planet Money. The subject was the shortage of artillery shell supplies during ongoing global conflicts. The podcast delved into the root cause of this scarcity, revealing a critical issue: the implementation of cost-cutting measures. These measures, while aimed at reducing expenses, had unintended consequences. They led to diminished inventory levels, impacting the availability of crucial parts. Furthermore, the reduction in manufacturing capacity—such as downsizing production plants and cutting back on skilled personnel—exacerbated the problem.

The Wrong Objectives: A Common Pitfall

Within my circle of process experts, we engaged in a thought-provoking discussion sparked by this podcast. Our conclusion was clear: the primary reason Lean and Continuous Improvement programs fail to meet expectations lies in their underlying objectives. Too often, well-intentioned leaders prioritize cost reductions above all else. However, this approach misses the mark.

Quality as the True North

Let’s illustrate this with a straightforward example. Imagine a manufacturer tasked with shipping 100 parts, with a production yield of 50%. Logically, they would need to maintain an inventory capable of producing 200 units to meet this demand. Now, if the sole focus is on cost reduction, they might trim the inventory down to just 100 units. However, this risky move could result in missed shipments.

Alternatively, consider a shift in perspective. Suppose the manufacturer aims to improve quality, raising the yield from 50% to 75%. In this scenario, they would only require 134 units in inventory to fulfill the same order. By addressing quality, cost reductions naturally follow.

The Right Approach: Customer-Focused, Worker-Centered, and Quality-Driven

Continuous Improvement programs should align with the organization’s core values. Rather than fixating solely on financial gains, they must prioritize quality. Here are the hallmarks of a successful program:

Customer Focus: Understand and meet customer needs. Quality products and services lead to customer satisfaction and loyalty.

Worker-Centered: Empower employees to contribute to improvement efforts. Their insights and engagement drive meaningful change.

Quality-Driven: Elevate quality as the central objective. When quality improves, costs decrease organically.

Cultivating a Productive Organizational Culture

In summary, Lean and Continuous Improvement programs thrive when anchored in quality. By emphasizing quality over cost, organizations can achieve sustainable improvements. Let’s shift the narrative from cost-cutting to quality enhancement—a transformation that benefits everyone involved.

A big shout out to Kay Schmidt for getting the conversation going!

References:

Picture and Planet Money Feb 21 edition:

https://www.npr.org/2024/02/21/1197958304/two-indicators-defense-spending-just-in-time

#continuousimprovement #qualitymanagement #leanmanagement #processimprovement #qualityfirst #organizationalculture #customercentricity

Ensuring Process Quality with Brown M&M’s

The Brown M&M’s Principle is a fascinating concept that highlights how small details can serve as useful indicators of larger issues. It’s named after the American rock band Van Halen, who cleverly used a “brown M&M’s clause” in their contracts with event organizers. Here’s how it worked:

The Backstory:

Van Halen was a hugely successful band in the 1980s, known for their hit songs like “Jump” and “Panama.” Their stage shows were elaborate and technically demanding, requiring extensive equipment and precise execution. As they toured globally, they faced challenges related to safety, quality, and compliance with their technical specifications.

The Brown M&M’s Clause:

Buried deep within their concert contracts, Van Halen included a seemingly trivial requirement: “There will be no brown M&M’s in the backstage area.”. If brown M&M’s were found backstage, the promoters would forfeit the show, and Van Halen would receive full compensation. At first glance, this demand seemed absurd. Why would a rock band care about the color of M&M’s?

The Real Purpose:

The brown M&M’s clause was a brilliant test of attention to detail. Van Halen knew that if organizers overlooked this small detail, they might also miss critical safety or technical requirements. By checking the M&M’s, the band could quickly gauge whether the entire production had been set up correctly. If brown M&M’s were present, it signaled potential problems—perhaps girders couldn’t support the weight, doors were too small, or flooring was inadequate.

The Impact:

David Lee Roth, Van Halen’s lead singer, explained: “If I saw brown M&M’s in that bowl, I’d line-check the entire production.” The clause helped them identify issues early, preventing disasters during shows. It wasn’t about the M&M’s; it was about meticulous execution and safety.

Applying the Principle:

In broader contexts, the Brown M&M’s Principle teaches us a valuable lesson: pay attention to seemingly minor details. These small deviations can serve as early indicators of larger problems lurking beneath the surface. But how does this relate to process quality and management?

The Brown M&M’s Principle Recap:

At first glance, the seemingly bizarre clause in their concert contracts: “There will be no brown M&M’s in the backstage area,” appeared trivial. However, it was a clever test of attention to detail. If brown M&M’s were found backstage, it signaled potential issues. The principle was about meticulous execution and safety, not just candy preferences, and an excellent application of Layered Process Audit (LPA).

Here’s how LPA works:

Multiple levels of management participate in the auditing process. Simple audits are conducted, focusing on high-risk processes. Integrated corrective and preventative actions are taken during or immediately after the audit.

LPA helps manufacturers and service providers:

· Take control of processes.

· Reduce mistakes, rework, and scrap.

· Improve work quality and the bottom line.

Conclusion:

Just as Van Halen’s brown M&M’s test revealed deeper problems, LPA helps you uncover hidden issues. By paying attention to the small details, you build a robust quality system. Remember, whether it’s rock concerts or manufacturing lines, the devil is often in the details.

If you want to explore LPAs further, consider reaching out to LightWorks—our experienced team can guide you toward smoother processes.

And a big shout-out to Michael Kimsal for the Van Halen reminder!

#processimprovement #qualitymanagement #processexcellence #attentiontodetail #manufacturingexcellence

Unlocking Continuous Improvement: Empowering Your Organization

Continuous improvement is not just a buzz phrase; it’s a fundamental concept that resonates with anyone seeking excellence. The path to delighting customers and maximizing margins lies in identifying and addressing inefficiencies, eliminating defects, and building products or services “right the first time.” But if this approach is so obvious, why do organizations still struggle to implement it effectively?

Business and function leaders are astute individuals who understand what needs to be done. However, they often seek guidance on the “how.” Let’s address some common questions:

- How to Implement a Continuous Improvement Initiative? Defining a practical and organization-specific continuous improvement program is crucial. LightWorks can provide thought leadership to tailor a program that aligns with your unique context.

- How to Sustain the Momentum? Deploying the program across your organization requires more than just enthusiasm. LightWorks offers training and ongoing support to ensure sustained progress.

- How Will People Know What to Do? Clear communication and alignment are essential. We help connect your employees’ daily work to the overarching vision, fostering a culture of improvement.

- Where to Find the Right Expertise and Talent? LightWorks brings expertise to the table. We guide you in assembling the right team and leveraging their skills effectively.

Our track record speaks for itself. We’ve partnered with both large and small organizations across various industries, implementing continuous improvement programs and fostering cultures of excellence. Our approach includes:

- Defining a Practical Program: We tailor continuous improvement initiatives to fit your organization’s size and needs.

- Deployment and Training: We ensure seamless implementation throughout your entire organization.

- Sustaining Progress: Our support perpetuates a cycle of action, adjustment, and improvement.

- Empowering Self-Sufficiency: We equip your organization to carry the torch independently.

The need for improvement is crystal clear, and the results of continuous improvement are well-documented. Let LightWorks be your catalyst for positive change. Contact us to embark on this transformative journey!

#analysisparalysis #continuousimprovement #excellence #profitboost #quality #customerexperience #leadership #culturechange #empowerment

From Problems to Possibilities: Embracing Opportunities

“What problem are you solving?”

I have been hearing this question with increasing frequency. Initially, this is a smart question. In one statement, it conveys the need to focus on solving a particular problem and in order to do so, the problem must be identified. This then leads into a devolving conversation about judging the problem: Is it big enough to solve? Is it more important to solve than our other problems? Why is it a problem? I am sure you have had this conversation and it usually ends inconclusively without decisions nor actions taken.

Reflecting on the question further, it predicates that a problem is required before an action can be taken. By the nature of the question, it is reactive and defensive. The Wright brothers are generally credited for inventing human flight. What problem were they solving? Before Kitty Hawk, very few humans voluntarily experienced flight, thus flying, although a strong desire of a few dedicated people, was not really a problem to solve; however, it is estimated that in 2019, pre-COVID, there were 4.5 billion air travel passengers. Using a more “modern” example, in 1979, Sony introduced a “play only” cassette tape player small enough that a person can easily take it on their daily commute while listening to their favorite cassette. It was named the “Walkman.” Before the Walkman, there was not an overwhelming problem that people cannot bring their audio content with them; however, the Walkman spurned the proliferation of personal audio devices. These devices are ubiquitous today and you likely have one with you at this moment.

Instead of asking “what problem are you solving?”, flip the orientation by asking “what opportunity are you going after?” By this simple flip, we can go from reactive to proactive, from playing defense to playing offense. Give it a try and let me know your experiences.

photo source: https://lnkd.in/gPtpskS8)